What is GSM?

GSM is the measurement used for paperweight. It also gives you a rough guide as to thickness of paper. A higher GSM means a thicker stock such as a sturdy card whereas a lower GSM such as 80gsm is thinner and more like your everyday home printer paper.

What is a bleed? Does every file I submit need to have a bleed?

A bleeds is the amount of product that will be cut of in the final stage of printing. We print on sheets bigger than required and then cut them down to size as the last step, a bleed is important as it makes sure your print isn’t left with a white edge after trimming by allowing a margin of error.

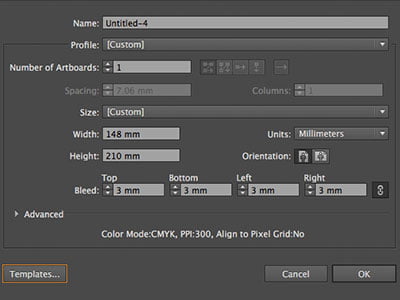

How do I add a bleed?

To add a bleed on Photoshop, open the image you would like to add a bleed to. Select “Image” then “Canvas Size” increase the width and height of the canvas by 3mm on all sides to include a bleed. Once you click ok you will see a border filled with the background colour around the edge of your document. Illustrator and InDesign have built in capabilities for adding bleed and trim.

Why is it more cost effective to print higher quantities?

For most lithographic print companies the cost is in the set up. This means lower quantities tend to have a higher cost per unit, making it more cost effective to print in larger quantities such as 500. For short runs it is better to use a digital printer as set up cost is low and therefore the cost of digital short runs is significantly cheaper.

What is proofing?

Proofing is the process of us checking to make sure your artwork is print ready. Just like you may proof read an essay after you have written it to check for mistakes, we do the same to your artwork to make sure it is print ready. Some examples of what we check for are low-resolution images, crop marks and bleed. It is important to remember we do not check for spelling mistakes and cannot be responsible for mistakes missed.

Turnaround?

The turnaround on a product is the rough length of time it takes for the print to be produced and delivered to you. The turn around differs between products, as some take longer than others in production.

What is stock?

Stock is what we actually print onto. Some examples of different stocks are orange peel texture, pearlescent and recycled.

What is lamination?

Lamination refers to the process of bonding clear plastic film to each side of your print. It is commonly used in Gloss, silk and matte finishes. Lamination is generally used to improve the appearance of printed materials however it can also make your print less likely to become dog-eared, make it water resistant and increases durability.

Special finishes

Uncoated – Uncoated stock is paper that hasn’t been coated with an agent to improve its brightness. Typically letterheads and loyalty cards are printed on uncoated stock so that they can be easily written on.

Foiling– Gold foil is commonly found on print like invitations. The foil is printed using heat and pressure to apply it to the chosen areas on a design.

Embossing – Embossing refers to pressing and image or text into your chosen stock to create a three dimensional design.

Di-cutting – Di-cutting is the process of cutting non-square customized shapes out of print. An example of di-cut print is heart shaped wedding invites.

Spot UV – Spot UV involves placing a very shiny and durable coating to printed materials and then setting with a UV light. Spot UV looks most effective when used on only on certain parts of designs.

Stock Textures

The word texture refers to how the stock feels. Leeds Printing Company offer many different types of textured card. Samples are available upon request.

Print samples

Samples are a selection of existing work that we send to you to take a look at to help you make a decision about the types of stock you’d like to print on. Samples are not test runs of the product you are looking to print but we do try to tailor the samples we send you around the products you require.

Back to Back

The term back to back refers to print being applied to both sides of a sheet of paper

Staple Bound

Staple bound or ‘Saddle stitched’ is a method of binding a brochure together. Folded sheets are gathered together and stapled through the fold line with staples. The staple is visible on the spine of the brochure and on the middle pages of the brochure. This is the most common method.

Perfect bound

Its possible that your document may be too thick to be saddle stitched, if this happens the best option for you would b to opt for a perfect bound document. Perfect binding is where the pages are joined together at the edge using glue. It is called perfect binding, as the finished product looks very neat with no exposed edges.

Ring bound

Popular with brochures used for presentations, the pages are bound together using a spiral of continuous wire or plastic looped through holes. An example of a product that uses ring binding is a calendar.

Finishing

Finishing refers to the final stages of the print process. This may include folding, cutting, binding and packaging.

Stock image(s)

A stock image is a professional high quality photo that is sold on a stock website such as Getty Images. Small companies who are unable to hire a photographer use often stock images.