In the printing world, a term that is of immense significance is “bleed”. This refers to the portion of the printed material that extends beyond the edge of the sheet before it’s trimmed. Essentially, bleed is the extra area that allows a document to seamlessly flow to the edge of a page, thereby ensuring that no white borders or lines are present around the edge after it’s been cut.

The role bleed plays in producing high-quality print materials is absolutely crucial. Without the use of bleed, the final product may showcase an unprinted edge due to the minor discrepancies that can occur during the final cut of your print job. Despite all efforts to cut accurately along the edge of your design, all printers, even those utilised by Leeds Printing Company, need to factor in a small margin of error in the cutting process. Bleed is the solution to this problem.

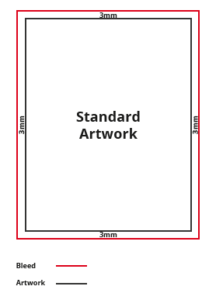

When a document is designed with bleed, it means that the design or print extends 3mm beyond the page’s edge. After the printing process, this extra area is trimmed off, which ensures that the design extends all the way to the edge of the page, leaving no white or blank space. Leeds Printing Company, whose services can be accessed at https://leedsprintingcompany.co.uk/, is well-versed in these professional printing techniques.

So, why does bleed play such a key role in the printing industry, including for firms like Leeds Printing Company?

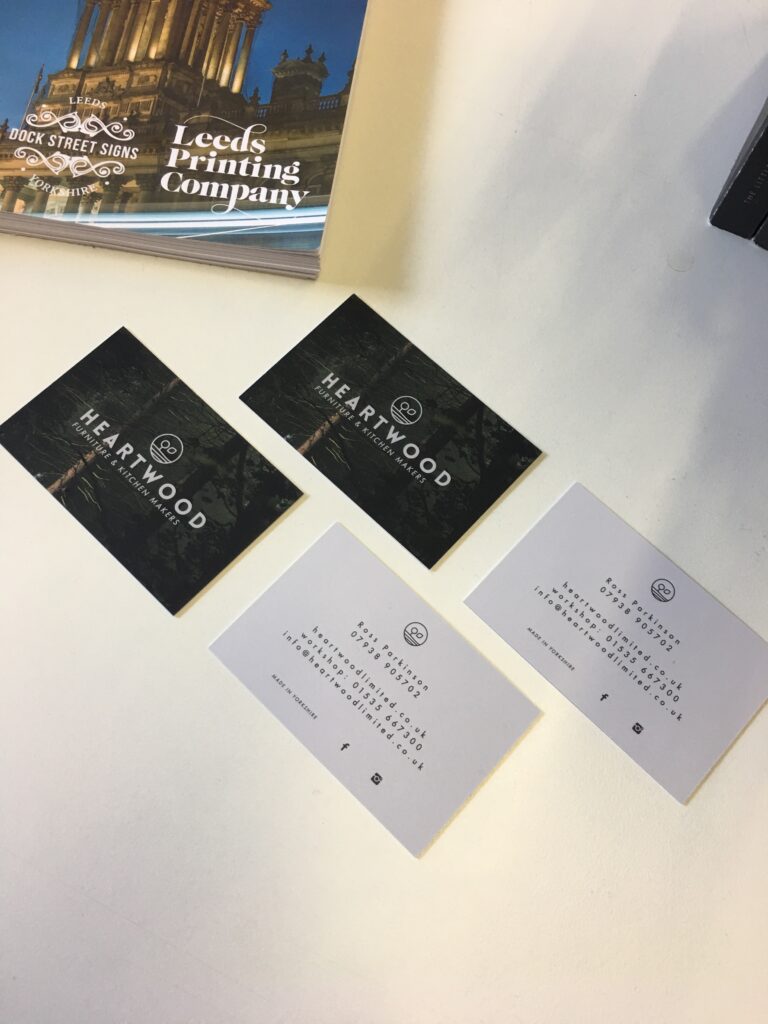

Primarily, bleed is essential for the creation of professional print materials. For an array of print products such as brochures, business cards, or flyers, an unexpected white border can make the design appear less professional. This can distract from your design’s impact and diminish the aesthetic appeal of the printed material.

Secondly, incorporating bleed compensates for minor inconsistencies that can occur during the printing and cutting processes. Despite the high-quality printers used at Leeds Printing Company, no machine can achieve 100% accuracy all the time. Paper can move slightly during printing, leading to a shift in the design’s placement. By including bleed, your design will still reach the edge even if a slight movement or misalignment occurs.

Thirdly, bleed ensures that your images, backgrounds, or colours extend all the way to the edge of your design, providing a more immersive and visually pleasing experience for the viewer. Without bleed, you risk your images being awkwardly cut off, or your background colour not reaching the edge of the page.

In conclusion, bleed is a fundamental yet often overlooked component of the printing industry, including at Leeds Printing Company. It plays an instrumental role in ensuring the quality and professionalism of printed materials. By extending the design beyond the final page size, bleed allows for any mechanical inaccuracies that may occur during the printing and cutting processes, providing a clean, borderless finish to the final product. Understanding and applying bleed effectively can be the difference between a satisfactory and an exceptional print job. It’s a seemingly minor detail with a significant impact on the overall look and feel of your printed materials.